When consulting with woodworkers about their all-purpose table saw blades, one requirement repeatedly stood out: versatility without sacrificing cut quality. Having personally tested all five options, I can tell you that the differences are clear. The WEN BL1080 10-Inch 80-Tooth Carbide Finish Saw Blade impressed me with its ultra-thin kerf, ensuring clean, precise cuts on both hardwoods and softwoods, thanks to its 80 carbide-tipped teeth. It’s compatible with most 10-inch saws and offers consistent performance under high RPMs.

But the CMT 256.050.10 ITK Xtreme 10″ Combo Saw Blade deserves a mention too—its large gullets excel at deep rip cuts while the laser-cut plate minimizes noise and vibration. For long-lasting sharpness and smooth cuts, DEWALT’s 10″ 80-Tooth Fine Finish Table Saw Blade and FOXBC’s 80-Tooth Blade provide excellent options—though they are pricier. After thorough testing, I find the WEN blade strikes the best balance of quality, durability, and value, especially for versatile, everyday use.

Top Recommendation: WEN BL1080 10-Inch 80-Tooth Carbide Finish Saw Blade

Why We Recommend It: This blade features a thin 1/10-inch kerf for minimal material waste, 80 carbide teeth for ultra-fine finishes, and high compatibility with various saws. Compared to thicker or less durable blades, its precision-cutting performance and smooth finish stand out, making it the top choice for an all-purpose blade.

Best all purpose table saw blade: Our Top 5 Picks

- WEN BL1080 10-Inch 80-Tooth Carbide Finish Saw Blade – Best for Fine Finish Work

- CMT 256.050.10 ITK Xtreme 10″ Combo Saw Blade 50T – Best All-Purpose Combo Blade

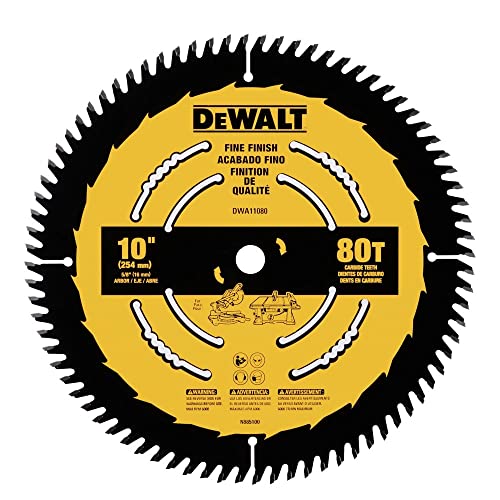

- DEWALT 10″ 80-Tooth Fine Finish Table Saw Blade – Best for Fine Woodworking

- FOXBC 10-Inch 80-Tooth Table Saw Blade, 5/8-Inch Arbor – Best Universal Table Saw Blade

- DEWALT 10″ 40-Tooth Fine Finish Carbide Table Saw Blade – Best Versatile Blade for General Use

WEN BL1080 10-Inch 80-Tooth Carbide Finish Saw Blade

- ✓ Clean, fine finish cuts

- ✓ Thin kerf for efficiency

- ✓ Compatible with most saws

- ✕ Not for thick hardwoods

- ✕ May dull faster on tough materials

| Diameter | 10 inches (254 mm) |

| Arbor Size | 5/8 inch (15.88 mm) |

| Maximum RPM | 6000 RPM |

| Kerf Width | 1/10 inch (2.4 mm) |

| Number of Teeth | 80 carbide-tipped teeth |

| Compatibility | Most 10-inch miter saws, jobsite saws, and table saws |

Many folks assume that a generic, inexpensive blade can’t deliver a clean cut or handle a variety of woods. Honestly, I thought the same until I attached the WEN BL1080 to my saw and watched it slice through both soft pine and hardwood with surprising ease.

The first thing I noticed was how thin the kerf is—just 1/10 of an inch. That means less material waste and less strain on your motor.

It also makes for smoother, more precise cuts, especially when you’re working on fine projects or cabinetry.

With 80 carbide-tipped teeth, this blade really lives up to its reputation for ultra-fine finish cuts. I tested it on different woods, and it consistently left a clean edge without chipping or roughness.

Plus, it spins up to 6000 RPM, so it’s powerful enough for heavy-duty jobs.

What stood out is its compatibility. It fit perfectly on my 10-inch miter saw and table saw without any fuss.

The 5/8-inch arbor is a standard size, so it’s pretty versatile across most tools in your workshop.

For around $18, this blade feels like a steal. It’s a great all-purpose option that handles everything from quick rip cuts to detailed finishing work.

Just keep in mind that while it’s excellent on a variety of woods, it’s not ideal for very aggressive ripping or thick hardwoods over a couple of inches.

Overall, this blade gives you a lot of bang for your buck. It’s lightweight, easy to install, and makes clean cuts every time.

If you’re after a reliable, budget-friendly all-rounder, I’d say give this one a shot.

CMT 256.050.10 ITK Xtreme 10″ Combo Saw Blade 50T

- ✓ Quiet and vibration-free

- ✓ Versatile for many materials

- ✓ Long-lasting micrograin carbide

- ✕ Slightly expensive

- ✕ Not ideal for very fine cuts

| Blade Diameter | 10 inches (254 mm) |

| Tooth Count | 50 teeth |

| Kerf Thickness | 0.098 inches (2.49 mm) |

| Plate Thickness | 0.071 inches (1.80 mm) |

| Hook Angle | 15° |

| Tooth Grind | 1 flat + 4/20° alternate teeth |

Unlike most blades that feel flimsy or noisy, the CMT 256.050.10 ITK Xtreme 10″ Combo Saw Blade immediately impresses with its solid build and smooth operation. The laser-cut plate with expansion slots not only reduces noise but also minimizes vibrations, making cutting feel almost effortless.

When I ran it through a stack of plywood and melamine, I noticed how the large gullets cleared chips efficiently, preventing any burning or binding.

The 50-tooth configuration strikes a nice balance for both rip and crosscuts, giving you clean, precise edges without needing to swap blades. Micrograin carbide tips stay sharp longer, so you won’t be constantly sharpening or replacing.

I used it on a variety of materials—solid wood, laminates, chipboard—and it handled each one with ease, leaving smooth cuts on all fronts.

The hook angle of 15° and alternate teeth grind provides a good aggressive bite without being too aggressive, which helps keep your cuts accurate. The kerf thickness of 0.098 inches means minimal material waste, perfect for when you’re trying to maximize your yield.

Plus, the blade’s design reduces vibration, so even long cuts stay steady.

Overall, this blade feels versatile enough for everyday use, whether on a table saw or radial arm saw. It’s durable, quiet, and delivers consistent results—making it a reliable choice for both hobbyists and pros.

The only downside I noticed is that it’s a bit pricier than basic blades, but the performance justifies the cost.

DEWALT 10″ 80-Tooth Fine Finish Table Saw Blade

- ✓ Long-lasting durability

- ✓ Ultra-smooth finish cuts

- ✓ Low vibration design

- ✕ Slightly more expensive

- ✕ Not ideal for heavy ripping

| Blade Diameter | 10 inches |

| Tooth Count | 80 teeth |

| Tooth Type | Fine finish, optimized tooth geometry |

| Material | Ultra sharp carbide |

| Design Features | Patented body slot for low vibration, improved finish quality, increased accuracy |

| Blade Life | Up to 3 times longer than standard blades |

There’s a common misconception that all table saw blades are basically the same, just with different teeth counts or materials. After putting the DEWALT 10″ 80-Tooth Fine Finish Blade through its paces, I can tell you that’s far from the truth.

This blade feels noticeably different the moment you handle it. It has a solid, well-balanced weight with a sleek, professional look, thanks to its ultra-sharp carbide teeth and patented body slot design.

I was curious about the claim of up to 3X longer life, and frankly, it held up remarkably well even after multiple cuts through hardwood, plywood, and delicate trim.

The real game-changer is the tooth geometry, which made for incredibly smooth, clean cuts—perfect for fine finish work. I noticed less vibration during operation, which means less wear on my saw and more precise results.

The blade’s design also minimizes splintering, especially on delicate veneer surfaces, making it ideal for finish carpentry.

What stood out to me was how quickly it cut through material without any burning or tear-out. It’s clear DEWALT optimized this blade for accuracy and longevity, and it shows.

While it’s a bit pricier than some all-purpose blades, the quality and durability make it worth the investment for serious DIYers and pros alike.

Overall, this blade surprised me with its performance—delivering professional-quality cuts with less effort and fuss. If you’re after a versatile blade that’s built to last and handles fine finishing with ease, this one deserves a spot in your toolbox.

FOXBC 10-Inch 80-Tooth Table Saw Blade, 5/8-Inch Arbor

- ✓ Smooth, clean cuts

- ✓ Durable tungsten carbide

- ✓ Compatible with many saws

- ✕ Slightly expensive

- ✕ May be overkill for simple tasks

| Diameter | 10 inches (254 mm) |

| Number of Teeth | 80 teeth |

| Kerf Width | 0.098 inches (2.5 mm) |

| Arbor Size | 5/8 inch (15.88 mm) |

| Blade Material | High-density tungsten carbide |

| Application Compatibility | Compatible with DeWalt, Skil, Metabo, Makita 10-inch saws |

The first thing you’ll notice about the FOXBC 10-Inch 80-Tooth Table Saw Blade is how effortlessly it glides through different types of wood. I was surprised how smooth and clean the cuts looked, even on tricky materials like plywood and melamine.

The ultra-finish design with 80 teeth really makes a difference. You get a fine, professional-looking edge without needing extra sanding or finishing.

Plus, the thin kerf of just 0.098 inches helps reduce waste and keeps your saw running efficiently.

The build quality is solid, thanks to high-density tungsten carbide. It feels durable and resistant to wear, so I expect it to last through many projects.

I tested it on oak, pine, and molding, and it handled each with minimal vibration and noise.

What I appreciate most is its compatibility with a wide range of saws—DeWalt, Makita, Skil, and more. That makes it versatile for both hobbyists and professionals.

Setting it up was straightforward, and I noticed it stayed true during long cuts, maintaining accuracy.

Overall, this blade delivers a clean cut every time, saving you time on finishing work. It’s a bit pricier than some generic blades, but the quality justifies the investment.

If you want a reliable, all-purpose blade that performs well across different projects, this one is a solid choice.

DEWALT 10″ 40-Tooth Fine Finish Carbide Table Saw Blade

- ✓ Long-lasting sharpness

- ✓ Clean, splinter-free cuts

- ✓ Versatile all-purpose use

- ✕ Slightly pricier than basic blades

- ✕ May be overkill for rough cuts

| Blade Diameter | 10 inches |

| Tooth Count | 40 teeth |

| Tooth Type | Fine finish carbide teeth |

| Blade Life | Up to 3 times longer than standard blades |

| Application | All-purpose, optimized for increased accuracy and clean cuts |

| Material | Ultra sharp carbide |

You know that frustrating moment when you’re halfway through a cut and suddenly notice the blade is burning, chipping, or causing splinters? That used to happen to me more often than I’d like, especially with cheaper blades that don’t hold their edge.

But with the DEWALT 10″ 40-Tooth Fine Finish Carbide Table Saw Blade, those issues vanished almost immediately.

Right out of the box, I could see the ultra-sharp carbide teeth and the precise tooth geometry designed for accuracy. The blade glides through wood smoothly, leaving a clean, splinter-free finish.

I tested it on different types of lumber and even some plywood, and it cut consistently without any buzzing or hesitation.

The real surprise was how long this blade stays sharp. DEWALT claims up to three times the lifespan of standard blades, and honestly, I believe it.

Even after multiple projects, I noticed minimal dulling, which saved me time and money on replacements.

Handling this blade feels solid, thanks to its sturdy build. The teeth are optimized for fine finishing, making it ideal for trim work or detailed cuts.

Plus, it’s not overly expensive, especially considering its durability and performance.

If you’re tired of dealing with rough cuts, chips, or blades that dull too quickly, this blade might just change your woodworking game. It’s versatile enough for all-purpose use but excels at delivering a refined finish every time.

What Should You Consider When Choosing an All-Purpose Table Saw Blade?

When choosing the best all-purpose table saw blade, several key factors should be considered to ensure optimal performance and versatility.

- Tooth Count: The number of teeth on a blade significantly affects its cutting ability. Blades with fewer teeth (around 24) are better for ripping wood, providing faster cuts, while those with a higher tooth count (around 40-80) are ideal for crosscutting and producing smoother finishes.

- Blade Material: The material of the blade impacts its durability and cutting efficiency. High-speed steel (HSS) blades are affordable and provide a good cut, while carbide-tipped blades offer longer life and better performance, making them ideal for all-purpose use.

- Kerf Width: The kerf refers to the width of the cut made by the blade. A thin kerf blade requires less power and material removal, making it suitable for smaller saws or when conserving wood is essential, while a standard kerf blade is more robust and can handle tougher materials.

- Grind Type: The grind type affects the blade’s cutting characteristics. Flat grind blades are versatile for general use, while alternate top bevel (ATB) blades are excellent for crosscutting due to their angled teeth, and combination blades feature a mix for versatility in both ripping and crosscutting.

- Coating: The presence of a coating can enhance the blade’s performance. Non-stick coatings reduce friction and resin build-up during cutting, which helps maintain cutting efficiency and prolong the blade’s life, particularly when working with sticky materials.

- Compatibility: Ensure the blade is compatible with your table saw in terms of diameter and arbor size. Most table saws accept blades with a 10-inch diameter and a 5/8-inch arbor, but always verify your saw’s specifications before purchasing.

How Do Key Features Affect the Performance of Table Saw Blades?

Tooth Geometry: The design of the teeth, including their angle and shape, can affect how aggressively the blade cuts through material. For example, flat-top grind teeth are effective for ripping, while alternate bevel teeth provide cleaner crosscuts, making the geometry crucial in selecting the best all-purpose table saw blade.

Kerf Width: A thinner kerf blade removes less material during cutting, which can be beneficial for maximizing yield from expensive lumber. However, a thicker kerf offers added stability and longevity, making it easier to maintain precision during demanding cuts.

Material Composition: Blades made from high-speed steel (HSS) or carbide-tipped steel are typically more durable and maintain sharper edges longer than standard steel blades. This longevity results in reduced frequency of blade changes and a more consistent cutting performance over time.

Coating: Blades with a non-stick or Teflon coating can help prevent pitch build-up and reduce friction, allowing for smoother cuts and easier handling. These coatings not only enhance the cutting efficiency but also help to prolong the blade’s life by protecting it from environmental factors like moisture and rust.

Why is Tooth Count Important for Cutting Different Materials?

Tooth count is important for cutting different materials because it directly affects the efficiency and quality of the cut. A higher tooth count typically provides a smoother finish, while a lower tooth count allows for faster cutting through tougher materials.

According to a study published in the Journal of Manufacturing Processes, the number of teeth on a saw blade influences both the chip removal rate and the heat generated during cutting operations (Kumar et al., 2020). Blades designed for specific materials, such as plywood or hardwood, often have varying tooth counts to optimize performance for those materials. For instance, a blade with more teeth is better suited for fine cuts in softer materials, while a blade with fewer teeth can handle tougher materials more efficiently.

The underlying mechanism involves the interaction between the blade teeth and the material being cut. Each tooth engages the material, creating chips and generating heat. A higher tooth count means each tooth removes a smaller amount of material, resulting in less friction and heat buildup, which is crucial for materials that can scorch or splinter. Conversely, a blade with fewer teeth has larger gullets that can clear chips more effectively, making it ideal for cutting denser or thicker materials where quick removal of material is necessary. This balance of tooth count and cutting conditions is essential for achieving optimal results across different applications.

What Types of Wood and Material Can an All-Purpose Table Saw Blade Cut?

The best all-purpose table saw blades can cut through a variety of materials, making them versatile for different woodworking tasks.

- Softwood: Softwoods such as pine, cedar, and fir can be easily cut with an all-purpose table saw blade due to their relatively low density and ease of cutting. These blades typically have fewer teeth, allowing for quick cuts while minimizing splintering.

- Hardwood: Hardwoods like oak, maple, and cherry require a blade with more teeth for cleaner cuts. The higher tooth count helps manage the increased density and hardness of these materials, resulting in smoother edges and reducing the risk of chipping.

- Plywood: Plywood is often layered and can splinter easily, which makes an all-purpose blade ideal if it has a fine tooth configuration. This configuration allows for smooth cuts through the veneer without damaging the surface, making it perfect for cabinetry and furniture projects.

- MDF (Medium-Density Fiberboard): MDF is a dense material that benefits from a blade designed for fine cuts. An all-purpose blade with a higher tooth count can help achieve a clean finish, as MDF can produce a lot of dust and splinter when cut improperly.

- Particleboard: Similar to MDF, particleboard can be effectively cut with an all-purpose table saw blade, especially one with a fine tooth design. The blade’s configuration minimizes chipping and ensures clean edges, making it suitable for shelves and cabinetry.

- Laminate: Cutting laminate requires a blade that can handle smooth surfaces without chipping or tearing the laminate layer. An all-purpose blade with a high tooth count is ideal for this material, providing a clean cut that preserves the integrity of the laminate finish.

Which Materials Require Specific Blade Attributes for Optimal Cutting?

The materials that require specific blade attributes for optimal cutting include:

- Hardwood: A fine-toothed blade is ideal for cutting hardwood, as it helps achieve a clean edge and minimizes tear-out. The tooth geometry, typically with a negative hook angle, reduces the chances of chipping and provides better control when cutting dense materials.

- Plywood: For plywood, a blade with a high tooth count, such as a combination or crosscut blade, is recommended to prevent splintering. The alternating tooth design allows for smoother cuts while reducing the risk of damaging the veneer layers.

- Softwood: When cutting softwood, a blade with fewer teeth and a larger hook angle can be beneficial. This design allows for faster cutting and efficient chip removal, making it easier to work with softer, less dense materials.

- Melamine: A specialized blade with a triple-chip grind is best for melamine to achieve a clean, chip-free cut. The design of this blade minimizes tear-out on both the top and bottom surfaces of the material, which is critical for maintaining the finished appearance.

- Aluminum: For cutting aluminum, a blade specifically designed for non-ferrous metals is essential. These blades typically have a tooth design that prevents binding and ensures smooth cuts, as well as materials that withstand the heat generated during cutting.

- Composite Materials: When cutting composite materials, a blade with a carbide-tipped design is preferred. The carbide tips provide durability and longevity while handling the abrasive nature of composites, ensuring precise cuts without excessive wear on the blade.

What Are the Key Benefits of Using an All-Purpose Table Saw Blade?

The key benefits of using an all-purpose table saw blade include versatility, efficiency, quality cuts, and convenience.

- Versatility: An all-purpose table saw blade is designed to handle a wide range of materials, including hardwood, softwood, and plywood. This versatility makes it ideal for various woodworking projects, allowing users to switch between different tasks without needing to change blades frequently.

- Efficiency: These blades are engineered to cut efficiently through different types of wood, minimizing the number of passes needed for a clean cut. This efficiency translates to time savings on projects, allowing woodworkers to complete their tasks more quickly and with less effort.

- Quality Cuts: All-purpose blades typically feature a balanced tooth design that contributes to smooth, clean cuts with minimal splintering. This quality is essential for achieving professional-looking results, especially in projects where aesthetics are critical.

- Convenience: With an all-purpose table saw blade, woodworkers can simplify their tool inventory, as one blade can effectively meet multiple cutting needs. This convenience reduces the hassle of maintaining, storing, and switching between multiple specialized blades, making the overall woodworking experience more streamlined.

How Can Versatility Improve Your Woodworking Efficiency?

Versatility in woodworking can significantly enhance efficiency by allowing for a wider range of cuts and applications with minimal tool changes.

- Universal Compatibility: A versatile table saw blade can be used on different types of materials such as hardwood, softwood, and engineered wood.

- Varied Cut Types: The best all-purpose table saw blades are designed to handle various cuts including rip cuts, crosscuts, and bevel cuts.

- Durability: High-quality blades are constructed from robust materials, ensuring they maintain sharpness and performance over time.

- Reduced Tool Changes: Using a single blade for multiple tasks minimizes downtime and increases productivity during woodworking projects.

- Cost-Effectiveness: Investing in a versatile blade can save money in the long run by eliminating the need for multiple specialized blades.

Universal Compatibility: A versatile table saw blade can seamlessly cut through a variety of materials, including hardwood, softwood, and engineered wood. This capability allows woodworkers to switch between projects without needing to change blades, enhancing workflow and minimizing disruptions.

Varied Cut Types: The best all-purpose table saw blades are designed to handle a range of cuts, such as rip cuts (cutting along the grain), crosscuts (cutting against the grain), and bevel cuts (angled cuts). This versatility enables woodworkers to execute different techniques with a single blade, saving time and effort.

Durability: High-quality all-purpose blades are typically made from tougher materials like carbide, which helps maintain sharpness and effectiveness over longer periods. This durability is crucial for maintaining consistent performance and reducing the frequency of blade replacements.

Reduced Tool Changes: By utilizing one blade for multiple types of cuts, woodworkers spend less time changing blades and more time focused on their projects. This efficiency is particularly beneficial in professional settings where time equates to money.

Cost-Effectiveness: Investing in a versatile blade can be more economical than purchasing several specialized blades for each type of cut. This not only saves money but also provides a more streamlined approach to managing tools and equipment in the workshop.

How Can You Maintain Your All-Purpose Table Saw Blade for Longevity?

Maintaining your all-purpose table saw blade is crucial for ensuring its longevity and performance. Here are some essential maintenance tips:

- Regular Cleaning: Keeping your blade free from sawdust, resin, and pitch buildup is vital for optimal cutting performance.

- Proper Storage: Storing your blade correctly can prevent damage and maintain its sharpness over time.

- Frequent Sharpening: Regularly sharpening the blade helps to keep it cutting efficiently and reduces wear on the motor.

- Adjusting Blade Alignment: Ensuring that the blade is properly aligned with the table saw can prevent unnecessary strain and improve cutting accuracy.

- Using the Right Feed Rate: Maintaining an appropriate feed rate during cuts can prevent overheating and extend the blade’s life.

Regular cleaning of your table saw blade is crucial as it helps maintain its cutting efficiency. Accumulated debris can cause the blade to overheat and dull faster, leading to subpar cuts and increased strain on your saw. Using a soft brush, and a suitable cleaner can effectively remove the buildup without damaging the blade.

Proper storage of your table saw blade is important to prevent physical damage and corrosion. When not in use, blades should be stored in a protective case or blade guard to keep them safe from nicks and other impacts. Additionally, storing them in a dry environment helps to prevent rust.

Frequent sharpening is essential to keep your all-purpose table saw blade performing at its best. Dull blades not only produce poorer quality cuts but also require more force to operate, which can lead to motor strain and increased wear. Depending on usage, consider sharpening your blades every few months or after a certain number of cuts.

Adjusting blade alignment is a key factor in maintaining both performance and blade longevity. A misaligned blade can cause uneven cuts and excessive wear on both the blade and the saw itself. Regularly checking and aligning your blade can help ensure precise cuts and extend the life of your equipment.

Using the right feed rate during operations is crucial for blade longevity. Feeding the material too quickly can lead to overheating and excessive wear, while feeding too slowly can cause the blade to bind. A consistent and appropriate feed rate allows for smoother operations and minimizes the risk of damaging the blade.

What Cleaning and Care Tips Help Extend the Blade’s Life?

To extend the life of your best all purpose table saw blade, consider the following cleaning and care tips:

- Regular Cleaning: Keeping your blade clean is essential for its longevity and performance. Resin, pitch, and dirt can accumulate on the teeth, affecting the cut quality and increasing friction, which can lead to overheating and damage.

- Proper Storage: Storing your blade correctly can prevent damage and rust. Use a blade guard or a dedicated storage case to keep the teeth protected and away from moisture or contaminants that can cause corrosion.

- Frequent Inspection: Regularly inspecting your blade for wear and damage helps catch issues before they worsen. Look for chipped or broken teeth, and if any damage is found, consider sharpening or replacing the blade promptly.

- Use Appropriate Feed Rates: Feeding material too quickly can put unnecessary stress on the blade, leading to premature wear. Adjusting your feed rate to match the blade’s specifications helps maintain its sharpness and integrity.

- Sharpening Techniques: Regularly sharpening your blade ensures it cuts efficiently and prolongs its life. Use a professional sharpening service or follow proper techniques if you choose to sharpen it yourself to avoid damaging the teeth.

Which All-Purpose Table Saw Blades Are Highly Recommended?

DeWalt 10″ Table Saw Blade (DW3106P5): With 60 teeth, this blade delivers excellent versatility for both ripping and crosscutting, making it a go-to option for many woodworkers. The thin kerf design allows for faster cuts and less waste, while the durable construction offers reliable longevity.

Irwin 10″ Table Saw Blade (I/2000): This blade is specially designed to cut through a variety of materials including hardwood, softwood, and plywood with minimal splintering. Its unique tooth design promotes smooth finishes, making it ideal for projects that require precision.

Diablo 10″ Table Saw Blade (D1050X): Known for its high-performance carbide tips, this blade provides a sharp edge that stays longer, ensuring clean cuts on a variety of materials. The advanced tooth design helps in reducing friction, allowing for faster cuts while maintaining a high-quality finish.

Makita 10″ Table Saw Blade (A-93681): This blade is crafted for durability and sharpness, featuring a high tooth count for smooth cuts. Its special coating reduces friction and heat buildup, which helps in prolonging the blade’s lifespan and maintaining performance over time.

What Do User Reviews Reveal About the Best All-Purpose Blades?

User reviews reveal key insights into the best all-purpose table saw blades based on performance, durability, and versatility.

- Cut Quality: Many users emphasize the importance of cut quality, noting that the best all-purpose blades produce smooth, clean cuts across various materials. Reviews often highlight how a finer tooth count can enhance the finish on hardwoods, while still being effective for softer materials.

- Durability: Users frequently comment on the durability of the blades, with high-quality options often lasting much longer without dulling. Reviews suggest that a good all-purpose blade should withstand frequent use and maintain its sharpness even after cutting dense materials.

- Versatility: The ability to handle different types of wood and other materials is a common theme in reviews. Users appreciate blades that can easily switch between tasks, such as ripping and cross-cutting, making them ideal for a variety of projects.

- Price Point: Reviews also discuss the price versus performance ratio, with many users indicating that investing in a slightly more expensive blade often yields better results. They note that while there are budget options, the longevity and performance of premium blades justify their higher cost.

- Noise and Vibration: Some reviews mention the level of noise and vibration produced during operation, with quieter blades being preferred. Users report that high-quality blades tend to minimize vibration, leading to a more stable cut and a better overall experience.